De totaalleverancier voor kaasmakerijen wereldwijd

Als ervaren full-service provider ondersteunt ALPMA klanten van idee tot eindproject

ALPMA

Complete oplossingen voor de gehele zuivelindustrie

ALPMA is het wereldwijd toonaangevende bedrijf voor de verwerking van melk en wei, kaastechnologie en snij- en verpakkingstechnologie.

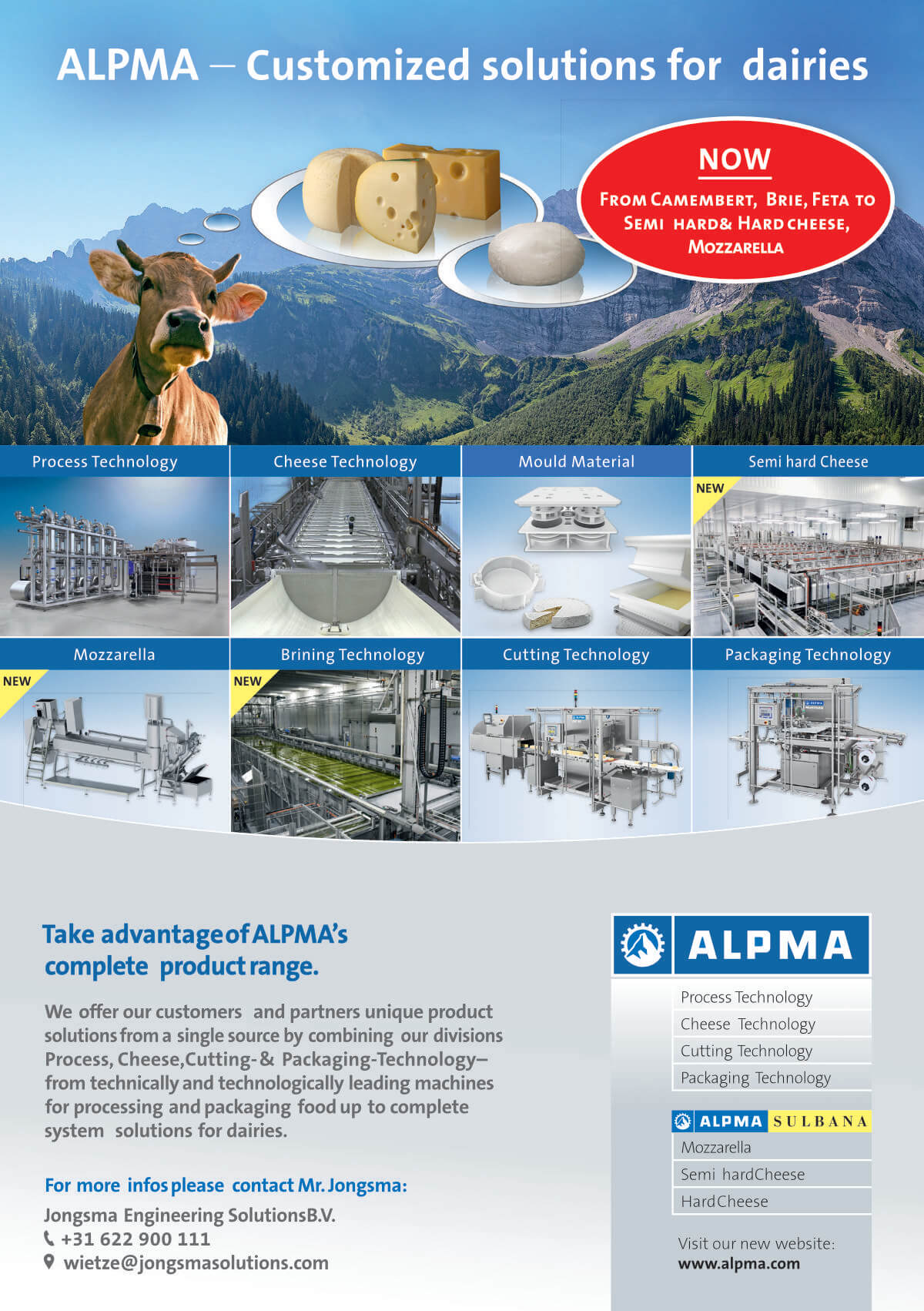

Naast de procestechnologische expertise beschikt ALPMA over de technologische competentie voor de kaasproductie van elke type kaas (twarog, zachte kaas, semi-harde kaas, harde kaas, pasta filata en tofu). ALPMA is expert in complete kaasproductielijnen, van de wrongelbereiding tot afvulsystemen, kaasvaten, kaasperssystemen, pekelbaden en de complete mechanisatie van de lijnen.

ALPMA staat bekend om innovatie en customised solutions. Zodoende levert ALPMA de Formatic en Coagulator die de meest efficiënte kaasproductie mogelijk maken. Laatstgenoemde innovatie is een volledig geautomatiseerde continue wrongelbereiding die zorgt voor de hoogst mogelijke opbrengst. Inmiddels zijn wereldwijd honderd Coagulators in werking.

Samen met dochteronderneming LTH Dresden levert ALPMA al meer dan 20 jaar innovatieve installaties voor de voedingsindustrie over de hele wereld. ALPMA is specialist voor het voorbewerken van melk voor zuivelfabrieken en het verder verwerken van zoete en zure wei tot hoogwaardige wei proteïne producten.

Voor meer informatie over onze expertise in plant engineering en alle toepassingen in membraanfiltratie verwijzen wij u door naar de homepagina van ALPMA.

ALPMA heeft officieel de – VeganoProt® – gelanceerd, haar nieuwe lijn voor Vegan Protein Diversity.

Plantaardig voedsel is in opmars en deze trend wordt weerspiegeld in de toegenomen populariteit van veganistische alternatieven voor kaas, yoghurt en melk. Uit een onderzoek van Mintel blijkt dat consumenten steeds meer openstaan voor alternatieve producten, wat resulteert in een golf van innovatie in plantaardig voedsel.

Zo is in de afgelopen drie jaar het aantal nieuwe veganistische kazen dat wereldwijd is gelanceerd, met gemiddeld 17 procent op jaarbasis toegenomen. Deze groei wordt gedreven door landen als Duitsland, de Verenigde Staten en Canada, waar de grootste zuivelfabrieken de markt hebben betreden om plantaardige varianten te lanceren onder hun bekende merken.

ALPMA werkt al heel lang met plantaardige eiwitten, zoals die van erwten en plantaardig zetmeel. Nu worden deze activiteiten samengebracht onder de merknaam VeganoProt®. Deze nieuwe lijn ondersteunt een diversiteit aan veganistische eiwitten – of het nu gaat om zetmeel of olieplanten of eiwitten die zijn verkregen door fermentatie.

Dus, ongeacht het type eiwit, ALPMA levert apparatuur op maat voor het produceren van plantaardige producten. De bewezen procestechnologie van ALPMA en de daaruit voortvloeiende verbeterde smaak van deze plantaardige producten maken ze aantrekkelijker en handiger voor de consument.

ALPMA biedt de klant zekerheid in geval van calamiteiten aan de membraaninstallatie. Door de gratis opslag van klant- en applicatie specifieke membranen bij ALPMA bespaart de klant tijd, opslagkosten en energie en verhoogt tegelijkertijd de productiebetrouwbaarheid van installaties.

Hoe gaat de membraan service in zijn werk? ALPMA werkt een zorgvuldig op maat gemaakte offerte uit voor de gewenste membraanmodules. Na het plaatsen van de bestelling zullen de membranen bij ALPMA worden opgeslagen onder de juiste condities in Dresden, en zorgt dat deze ten alle tijden binnen 3 werkdagen beschikbaar zijn voor de klant. Hierdoor kunnen plotselinge productieproblemen worden opgevangen op zeer korte termijn.

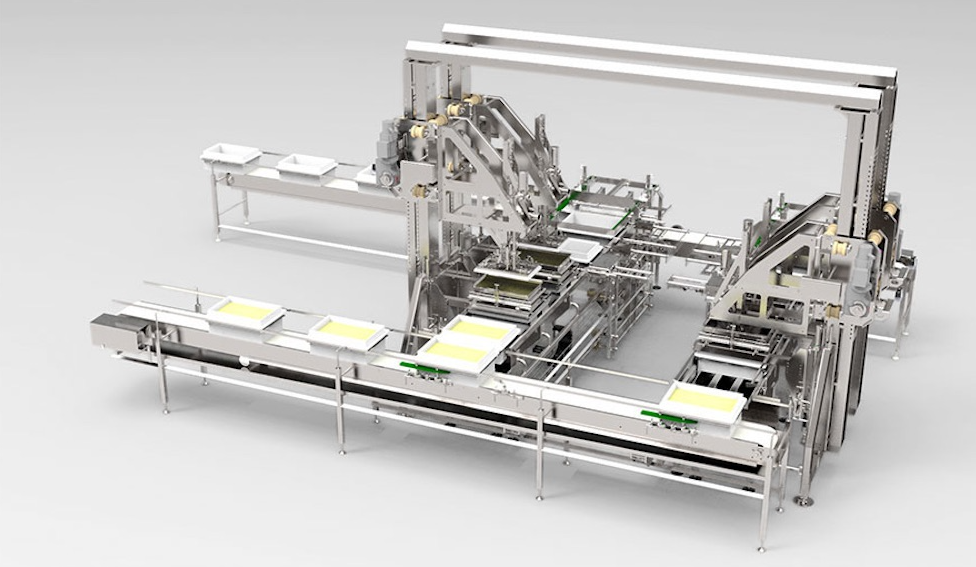

ALPMA ontwerpt en produceert systemen voor een breed scala aan kaassoorten en bedrijfsgroottes. Een ALPMA-lijn wordt modulair ontworpen en kan daardoor stapsgewijs worden aangepast aan de groeiende omvang van het bedrijf.

De variëteit aan halfharde kazen is enorm. Daarom vereist elk product een individuele productielijn. Om deze reden bundelt ALPMA zijn expertise met SULBANA om u een uitgebreid scala aan oplossingen en technieken te presenteren.

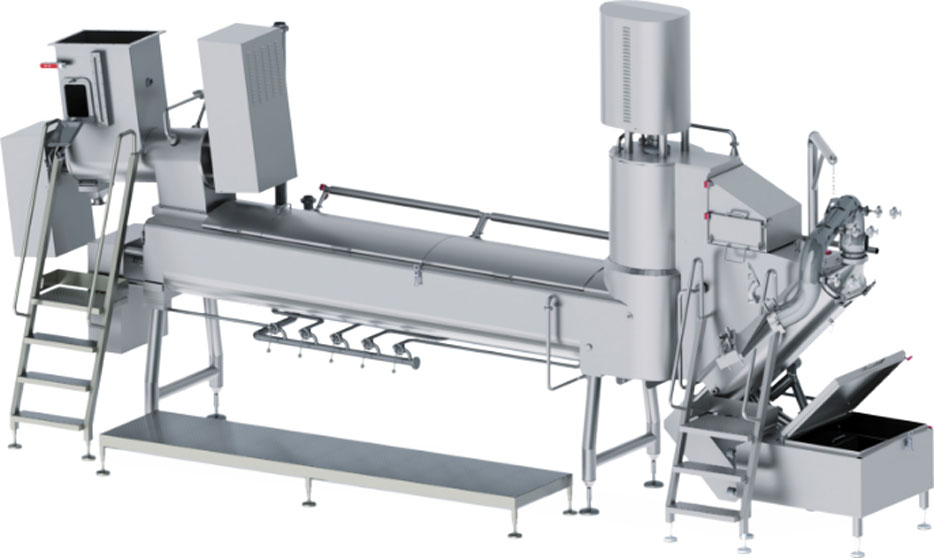

Als innovatiemotor in de pasta filata en mozzarella, heeft Sulbana een uitstekende reputatie opgebouwd. Om synergieën te optimaal te benutten, valt de divisie kaasbereidingstechnologie van SULBANA nu onder het dak van de ALPMA-groep. Dit stelt ALPMA in staat klanten een op maat gemaakte en uitgebreide service te bieden op het gebied van kaasbereidingstechnologie.

Als innovatiemotor in de pasta filata en mozzarella, heeft Sulbana een uitstekende reputatie opgebouwd. Om synergieën te optimaal te benutten, valt de divisie kaasbereidingstechnologie van SULBANA nu onder het dak van de ALPMA-groep. Dit stelt ALPMA in staat klanten een op maat gemaakte en uitgebreide service te bieden op het gebied van kaasbereidingstechnologie.

De totaalleverancier voor kaasmakerijen

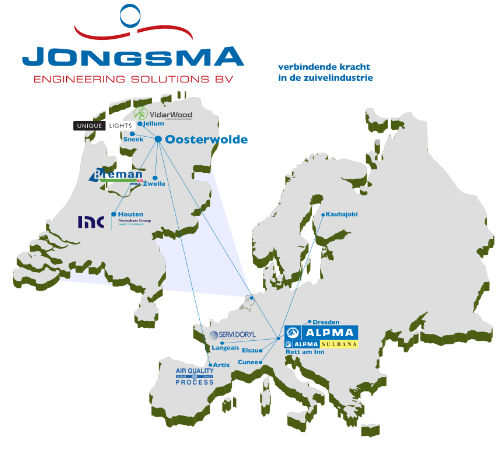

Het hoofdkantoor van ALPMA is gevestigd in Rott am Inn/Bavaria (Duitsland). Met haar dochterondernemingen en agentschappen en meer dan 900 medewerkers wereldwijd zorgen we voor en werken we samen met onze klanten om het succes van ALPMA te verzekeren. Aangestuurd en ondersteund door twee CEO’s met ervaring, een sterk leiderschap en een internationale, overkoepelende bedrijfsstrategie. Dit stelt ALPMA in staat om met expertise en flexibiliteit te reageren op regionale en lokale vraagstukken waarbij we kunnen schakelen in de moedertaal van de klant.

Bedrijfsvereniging met extra voordelen

De samenwerking van ons bedrijf met de zuivelfabriek Alpenhain en het gespecialiseerde verpakkingsbedrijf FRISCHPACK biedt onze klanten een uniek bijkomend voordeel: de zeldzame mogelijkheid om in de directe omgeving veel ALPMA-machines in bedrijf te zien.

Door nauwe communicatie met gebruikers van onze machines binnen deze vereniging krijgen we niet alleen gekwalificeerde technologische feedback, maar ook wensen en suggesties met betrekking tot onze installaties. Onze klanten profiteren van deze waardevolle informatie – hiermee zijn de nieuwste vormen van ALPMA-technologie binnen deze vereniging beproefd en getest.

Brochure

Customized solutions for dairies

Meer weten over de oplossingen van onze partner ALPMA? Lees dan de bijgaande brochure. Wanneer je geïnteresseerd bent in deze oplossing voor jouw bedrijf, neem dan contact op via het formulier onderaan deze pagina.

Update

Laatste Alpma Nieuws

Anuga FoodTec 2024 – coming soon!

Over minder dan 2 maanden en dan vindt de Anuga FoodtTec 2024 plaats in Keulen. Van dinsdag 19 t/m vrijdag 22 maart om precies te

Succesvolle capaciteitsuitbreiding bij Rouveen Kaasspecialiteiten

In 2007 nam Rouveen Kaasspecialiteiten de FORMATIC van ALPMA in gebruik. De installatie is een unieke, innovatieve afvulinstallatie geschikt voor de productie van semi-harde en

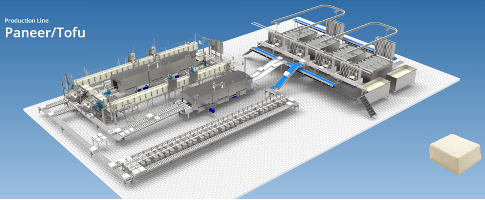

Tofu (plantaardig kaasalternatief) en Paneer wereldwijd in opkomst

Met de juiste apparatuur zijn kaasmakers in staat om de groeiende markt van Tofu als Paneer aan te boren. Beide producten zijn de laatste jaren

ALPMA News & Trends – Proceslijnen voor plantaardig voedsel

In de nieuwste editie van ALPMA News & Trends worden actuele onderwerpen en projecten uitgelicht, waaronder de ontwikkelingen van VeganoProt, ALPMA’s lijn voor Vegan Protein Diversity, welke vorig jaar is gelanceerd.

ALPMA lanceert nieuwe merknaam VeganoProt®

ALPMA heeft officieel de – VeganoProt® – gelanceerd, haar nieuwe lijn voor Vegan Protein Diversity. Plantaardig voedsel is in opmars en deze trend wordt weerspiegeld

Gisbert Strohn (CEO ALPMA) met pensioen

Sinds 1 januari 2023 is Gisbert Strohn, lange tijd directeur van de ALPMA Group, met pensioen. Hij leidde ALPMA bijna twee decennia. In oktober 2003